Get Free Shipping On Any Orders Above $99 🎉

MinderRC DH30 OLED Screen Portable Spot ,Welder For Max 0.15mm Nickel Strip Spot ,Welding Machine 18650 21700 5000mAh Lipo Include

$135.99$176.7923% off

Color: DH30 No Adapter

Discount only available in

Please full charging spot welder before first using

Note: We suggest you choice the DH30 with 18W power adapter,if you not have a power adapter 5V over 2A current,can not charge or charge slow for the high discharge Lipo battery inside the spot welder!

We suggest directly connect the black charging wire coming with spot welder from power adapter to spot welder;

We not suggest use PD charger or connect any other voltage current meter,because some PD charger and wire can not output a 5V voltage,type C to type C connect will have some charging problem!

Spot Welder include high discharge lipo battery,for safe delivery,it have low power,inside IC control charging current when battery is low power,

In the case of low power, there may be a low voltage alarm and the screen is not bright, continue to charge, the screen will return to normal charging,we suggest charing more than 30 minutes.

DH30 Specifications:

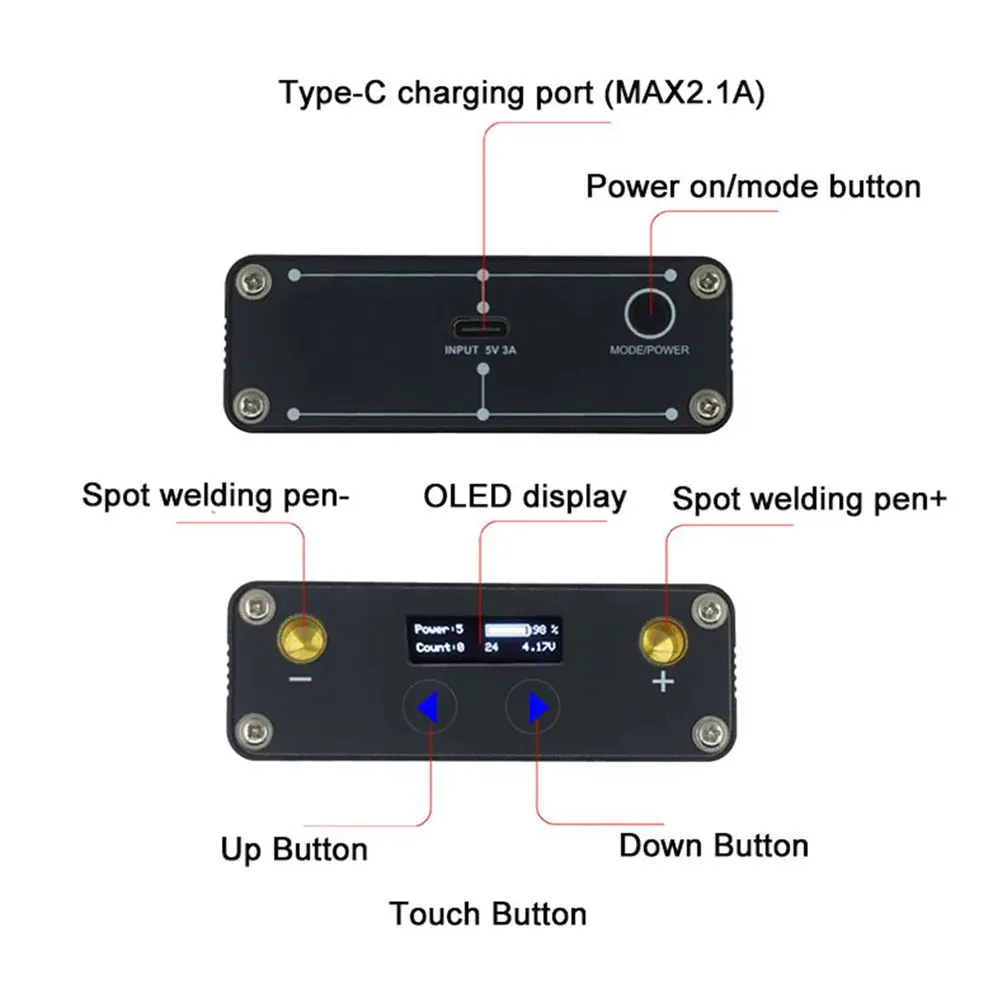

Screen: 0.91 Inch OLED

Material: Metal Case

Battery Capacity: 5000mAh

Welding Output: MAX 650A

Charging Port: Type-C

Product Weight: 302g

Product Size: 103x83x29mm

DH30 Packaging Include

1 x Mini Spot Welder

1 x Welding Pen

1 x Type C Charging Cable

1 x 0.12mm*8mm*2m Nickel Plated Steel Belt

1 x User Manual

1 x EU/US/UK Power Adapter (Optional)

How to Using spot welder

Long click the button about 3 seconds then release to power on or off the spot welder

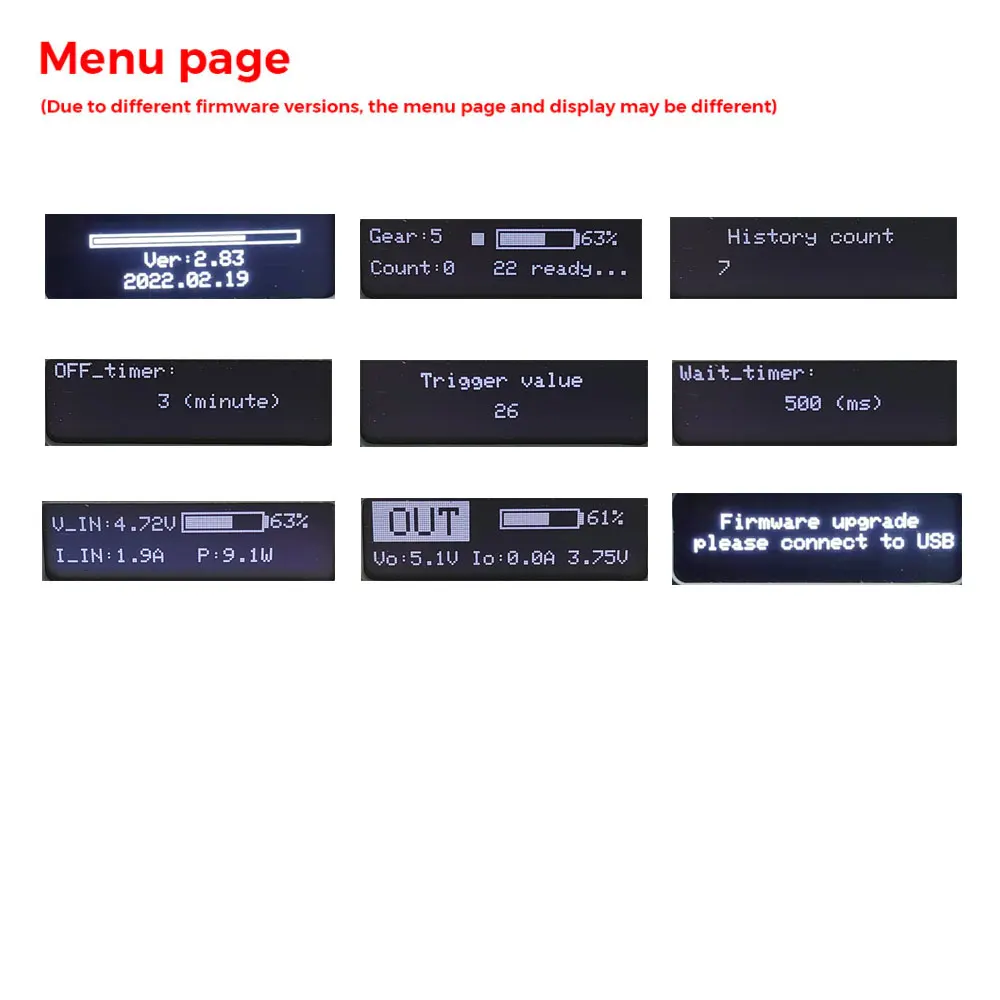

Try different spot welding power from low to high,we suggest use gear 17 or 18 to welding 0.12mm Nickel steel strip,if set the MAX gears,Nickel belt will be broken down or spot welder will power off to protection mode,It is not that the higher the power, the better welding effect is. When welding, you only need to lightly touch the soldering pen to the nickel strip, not pressing hard,need to keep the surface of the nickel belt and the battery flat.

The following welding is the wrong method:

1. Welding two nickel strips of the same thickness up and down will cause most of the current to pass through the welding, resulting in unstable welding

2. Not cut and weld the entire roll of nickel tape may cause welding current to be transmitted to the entire roll of nickel tape, resulting in unstable welding

Correct welding method:

Before welding, it is necessary to fully charge the spot welding machine. The power of the spot welding machine just received is insufficient due to safe transportation

The thickness of the solder needs to be thicker than the thickness of the nickel strip. The spot welding needle gently contacts the nickel strip and cannot be pressed hard. For 0.12 nickel plated nickel strips, it is recommended to set the gears 17-18